Flattener – compound-curved plate expansion for Windows

MSDEV – developable plate expansion for Windows

Flattener is the compound-curved plate expansion utility offers you these cost-saving benefits:

1. considerable acceleration of the assembly process

2. accurate lofting and NC machining

3. minimal material scrapping

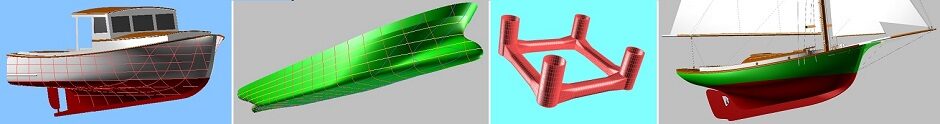

Plate expansion is the process of designing a flat blank to be cut from stock and subjected to a compounding process in order to form a curved plate. The primary product of plate expansion is an expanded outline for each individual plate. It is extremely valuable in the manufacturing process to have accurate expansions for plates, because accurate cutting is relatively simple while the material is flat, and having formed 3D parts which fit to each other accurately without trial and error or field trim greatly accelerates the assembly process. It is also useful to be able to mark on the expanded blank the mapped positions of 3D features such as points (MultiSurf magnets), curves (MultiSurf snakes), and contours (stations, waterlines, etc.).

Flattener is a compound plate expansion utility based on AeroHydro’s unique flattening technology which was developed in 1988-89 and patented (U.S. and Canada) in 1990. The unique feature of the AeroHydro plate expansion technology is that it takes explicit account of the variable distribution of in-plane strain required to produce the specified 3D curvatures.

This solution enables accurate lofting and NC cutting of blanks which, through application of a suitable compounding process (e.g. die pressing, roller planishing, peening, line heating, etc.), evolve into curved plates precisely fitting their prescribed positions on the hull.

Flattener is fully integrated MultiSurf. The basic process to follow is to design the 3D plates in MultiSurf, then run Flattener to calculate the flat plate shapes. Flattener output is in the form of DXF and/or 2DD files which include (for each plate):

- the expanded plate outline

- specified point, curve, and contour markings on the plate

- a contour map of strain distribution

- the triangular mesh utilized for the solution

Other features include:

- options for expansion only, contraction only, as well as both expansion and contraction

- strain may be isotropic (equal in all directions), or anisotropic

- plates may be expanded individually or in groups

- specification of the ratio of least to greatest strain

And, as always with AeroHydro products, Flattener comes with comprehensive and illustrated documentation including examples.

Click here for an example and sample output

Click here to see how the Flattener integrates with SurfaceWorks and SolidWorks

Price: See Pricelist

Reference: The mathematical basis and validating calculations for the AeroHydro compound-curved plate expansion process are presented in Letcher, J. S. Jr.: “Lofting and Fabrication of Compound-Curved Plates,” Journal of Ship Research, vol. 37, (1993), pp. 166-175.